Created by: Cristine | Published on: October 11, 2024

Choosing the wrong cellulose ethers for putty powders can lead to poor adhesion, cracking, or other performance failures. This article will guide you in selecting the right cellulose ether for optimal application results.

To select the right cellulose ethers, consider factors like application conditions, the intended function of the putty powder, and the specific properties of different types of cellulose ethers.

Let’s dive deeper into the key considerations when choosing the correct cellulose ethers for your putty powders.

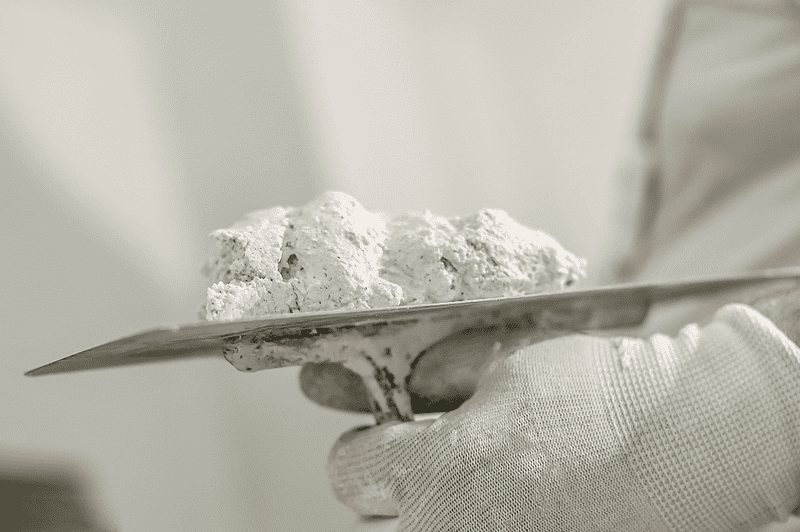

Cellulose ethers are important in putty powder formulations. They help keep water in, making the putty easier to work with and stickier too. They do the stuff that gives the putty its texture and keeps it from slumping off the putty knife while you’re trying to get it on the wall.

All this is why it’s so important to pick the right cellulose ether for your putty. That’s how you get the good performance during construction and make sure your putty is gonna last.

In putty powders, the cellulose ethers you see used most often are hydroxypropyl methylcellulose (HPMC), hydroxyethyl cellulose (HEC), and methyl hydroxyethylcellulose (MHEC). Each one behaves a little differently:

Understanding these differences helps you choose the right cellulose ether based on your specific needs.

The conditions in which you’re working are really important when you’re picking your cellulose ether. The stuff like temperature, humidity, the kind of surface you’re working on (like drywall or concrete). That’s the stuff that affects how your putty powder is gonna work.

So, you wanna match up the properties of your cellulose ether to your working conditions. That’s how you get your putty to work better and look nicer.

When choosing cellulose ethers, look for specific product features that align with your putty powder’s intended use:

Note how each type of cellulose ether can help you get the performance you want during application and after the job’s all done.

Of course you want good quality, but you have to think about how much it costs you, too. The really good cellulose ethers cost more. But they usually save you on callbacks for stuff like cracks and peeling later. On the other hand, if you choose the cheap route, you might give up good performance. Then you end up paying more in callbacks.

That’s pretty much how you need to weigh the price versus what you need your putty powder to do.

Make sure you pick the right cellulose ether for your putty powder. You do that, and your putty powder works how you want it to work.

What do you need to think about? The environment, the cellulose ether’s properties, how much it costs—stuff like that. Make your pick based on your job.

Please let me know your application needs, and we will recommend the most suitable product for your business.We are also happy to send you free samples for testing.

68 Tanan Road, Shijiazhuang, Hebei, China

Cellulose Ether Manufacturer

Typically replies within minutes

Any questions related to How to Choose the Correct Cellulose Ethers for Putty Powders??

Nancy

🟢 Online | Privacy policy

Chat for quality HPMC & factory prices!

Please tell us what you need and we will contact you as soon as we receive it!