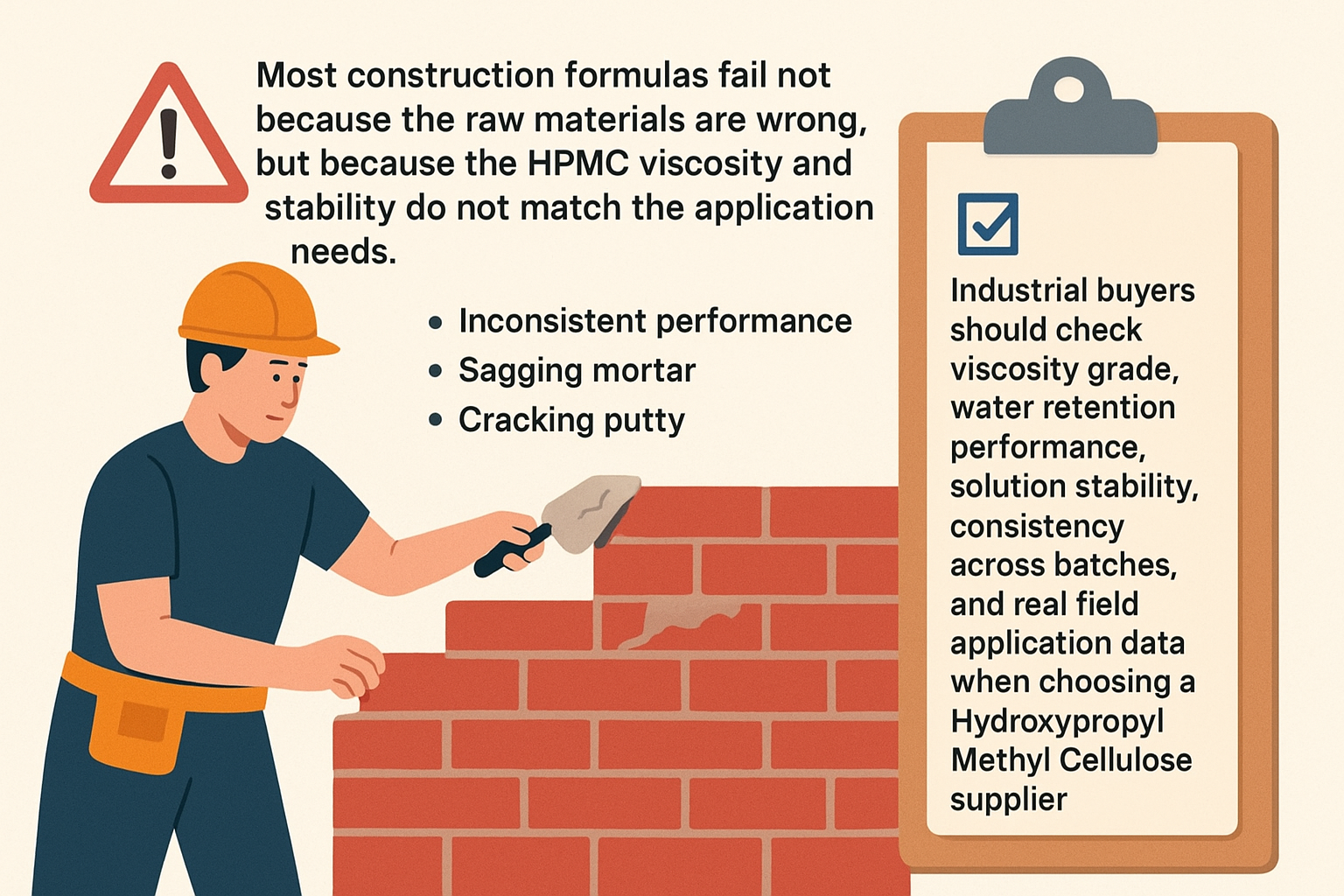

Most construction formulas fail not because the raw materials are wrong, but because the HPMC viscosity and stability do not match the application needs. Many industrial buyers face inconsistent performance, sagging mortar, and cracking putty due to low-grade cellulose — and it damages brand reputation.

Industrial buyers should check viscosity grade, water retention performance, solution stability, consistency across batches, and real field application data when choosing a Hydroxypropyl Methyl Cellulose supplier. Evaluate technical support, lab capability, certifications, and large-scale supply stability.

HPMC supplier evaluation

I have worked with many construction buyers who came to me after facing application failures from unreliable suppliers. I always tell them this: choosing HPMC is not just about a viscosity number. It is about real construction performance, supply reliability, and long-term cooperation. If you want consistent formulation results, keep reading, because the viscosity mechanism and grade selection matter more than people think.

What Is the Role of Hydroxypropyl Methyl Cellulose Viscosity in Cement-Based Materials?

Most mortar failures happen when HPMC viscosity does not match the cement system. Developers struggle with poor workability, low water retention, or collapse issues, and waste time adjusting formulas again and again.

HPMC viscosity controls water retention, thickening, open time, and workability in cement-based materials. Higher viscosity provides stronger adhesion and anti-sagging, while medium viscosity improves workability and leveling. Right viscosity keeps water in the mortar long enough for strong hydration and smooth construction.

HPMC viscosity role

When I first worked with a Southeast Asian tile adhesive brand, they had significant tile slip on large ceramic tiles. Their existing HPMC claimed to be 200,000 cps, but its real solution behavior was weak. After switching to our modified high-viscosity cellulose, the sag resistance improved immediately. They told me, “Now the tiles stand like soldiers on the wall.”

Key Viscosity Functions

| Function | Explanation |

|---|---|

| Water retention | Prevents cement dehydration for strength build-up |

| Thickening / rheology | Controls flow, spreadability, and anti-sagging |

| Open time extension | Allows longer adjustment time at job-site |

| Workability | Creates smoother troweling and easier mixing |

I always advise buyers to request consistency tests, not just viscosity numbers. True quality appears in real application flow tests, anti-slip tests, and retention experiments. Even TCNA and EN 12004 standards emphasize adhesive consistency and sag-resistance performance, not just viscosity values.

Reference: TCNA Handbook (tile industry standard) and EN 12004 classification guidelines for tile adhesives.

How Different HPMC Viscosity Grades Impact Mortar, Tile Adhesive, and Wall Putty Performance?

Choosing viscosity by guesswork leads to performance risk. Some suppliers sell one grade for all uses — this is a red flag for industrial buyers.

Low viscosity improves wetting and workability in putty. Medium viscosity improves water retention and leveling in plaster and skim coat. High viscosity provides strong sag resistance and bonding in tile adhesive and thick mortar systems.

HPMC viscosity grade performance

In Africa, I supported a distributor who supplied tile adhesive to many government housing projects. Their formulas used medium-viscosity HPMC because a previous supplier told them it was “universal.” Tiles kept sliding under hot and windy job-site conditions. After reformulating with our high-viscosity modified type, installation stability improved and their complaints dropped to almost zero.

Viscosity Grade Comparison

| Viscosity Level | Typical Range | Best For | Key Benefits |

|---|---|---|---|

| Low | 20,000–40,000 cps | Wall putty, skim coat | Good leveling, smooth workability |

| Medium | 50,000–100,000 cps | Plaster mortar | Good retention, easy spreading |

| High | 150,000–200,000+ cps | Tile adhesive, EIFS mortar | Strong anti-sag, longer open time |

What To Test

- Sag resistance on large tiles

- Water retention in high-temperature conditions

- Open time under wind exposure

- Mortar consistency after mixing

Industry note: ASTM C270 specifies mortar water retention performance guidelines. This aligns with selecting proper viscosity for cement hydration performance.

How to Select the Best Hydroxypropyl Methyl Cellulose Viscosity Grade for Your Construction Application?

Many buyers ask, “Which viscosity is best?” But viscosity is only one part. Climate, substrate, tile type, and local sand quality matter too.

Select viscosity based on application type, formula thickness, climate conditions, and performance testing. For wall putty choose low–medium viscosity. For plaster choose medium. For tile adhesive choose high viscosity modified grades for anti-slip and open time performance. Always run field tests before bulk purchase.

Selecting HPMC viscosity

One client in Malaysia used imported sand and got sticky mortar behavior. They thought viscosity was too high — but the real issue was a poor sand-cement ratio and high humidity. We adjusted both HPMC grade and dosing, and trained their production team. Performance became stable, and they secured a 5-year supply contract for municipal projects.

Selection Table

| Application | Recommended Viscosity | Notes |

|---|---|---|

| Wall putty | 20,000–60,000 cps | Smooth finish, easy polish |

| Skim coat | 40,000–80,000 cps | Better leveling, moisture retention |

| Plaster | 80,000–100,000 cps | Stronger water retention |

| Tile adhesive | 150,000–200,000+ cps | Anti-slip, extended open time |

Checklist Before Ordering

- Ask for COA + viscosity curve data

- Check batch-to-batch consistency

- Request mortar application test report

- Verify factory scale and automation

- Confirm shipping capacity and stock ability

(Tip: Large suppliers can stabilize quality and delivery.)

For technical references, you may check:

- TCNA (Tile Council of North America) installation guidelines

- EN12004 tile adhesive European test standards

These show how adhesive consistency and vertical slip performance are evaluated.

Conclusion

Right HPMC viscosity is the key to smooth construction, strong bonding, and stable supply. Always match viscosity to application and verify real-world performance before bulk purchasing.