Kehao Hydroxyethyl Cellulose ether (HEC) are a range of non-ionic celluloseethers specifically designed for aqueous systems.The products are made fromnatural polymers and are produced through a series of chemical processes toprovide a high price-performance ratio in coating applications.

Kehao Hydroxyethyl cellulose (HEC) has excellent thickening efficiency, stable thickening effect, excellent in-can apperance good workability in latex paints,andgood compatibility with pigments,emulsions and additives in water-based paints,resulting in good color acceptance.

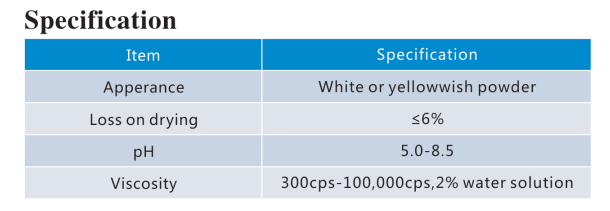

Also Kehao HEC has a wide range of products models,customers can choose theright specification of cellulose ether products according to different coating formulationsystems.

HEC can form a protective film in mortar to reduce water evaporation and keep the mortar moist, avoiding cracking and shrinkage due to rapid drying. This helps to improve the compressive strength and bond strength of the mortar.

HEC can increase the viscosity and viscosity of mortar, so that the mortar has a better fluidity, enhance the construction performance and self-leveling performance of mortar.

HEC can slow down the hydration rate of cement, control the setting time of mortar, so that the mortar has enough time to harden and dry, improve the compressive strength and durability of mortar.

HEC can improve the ease of mortar, improve the smoothness of construction, reduce the contraction and cracking of mortar, increase the impermeability and water resistance of mortar, so as to improve the quality and service life of mortar.

Appropriate amount of cHEC can improve the mechanical properties of mortar such as compressive strength, flexural strength and bonding strength, and enhance the durability of mortar.

The main component of RDP powder is polymer resin, which has good bonding performance. By adding appropriate amount of RDP powder, the bonding between putty powder and substrate can be significantly improved, thus improving the adhesion of putty layer. This helps to ensure the durability and stability of the putty layer, effectively preventing the occurrence of phenomena such as cracking and peeling of the putty layer.

As RDP powder contains polymers, these polymers are able to form an elastic network structure in the putty layer, thus improving the putty powder’s crack resistance. This is especially important in exposed parts of the building, such as the exterior walls, to extend the service life of the building.

RDP powder has good water resistance, which can improve the water resistance of putty powder. In a humid environment, if the putty layer is not water-resistant, it is prone to mold, blistering, peeling and other phenomena. By adding RDP powder, the water resistance of putty layer can be improved, so that it can still maintain good adhesion in a humid environment.

RDP powder can also improve the construction performance of putty powder, such as easy to scrape, easy to sand and ductility, to ensure construction efficiency and construction quality. This helps to improve construction efficiency while reducing the occurrence of construction defects.

Tell us your application, we will provide customized solutions and technical guidance for you!

68 Tanan Road, Shijiazhuang, Hebei, China

Cellulose Ether Manufacturer

Typically replies within minutes

Any questions related to HEC?

Nancy

🟢 Online | Privacy policy

Chat for quality HPMC & factory prices!

Please tell us what you need and we will contact you as soon as we receive it!