Many construction producers struggle to pick the right cellulose ether. Wrong selection often causes sagging mortar, poor water retention, and job-site complaints. This mistake wastes time, reduces quality, and hurts brand trust.

Hydroxypropyl Methyl Cellulose (HPMC) gives stronger water retention, better consistency, and wider mortar compatibility than MHEC and HEC in construction applications. While MHEC works well in tile adhesive and plaster, and HEC performs best in coatings, HPMC remains the most reliable and flexible option for cement-based and gypsum-based dry-mix products.

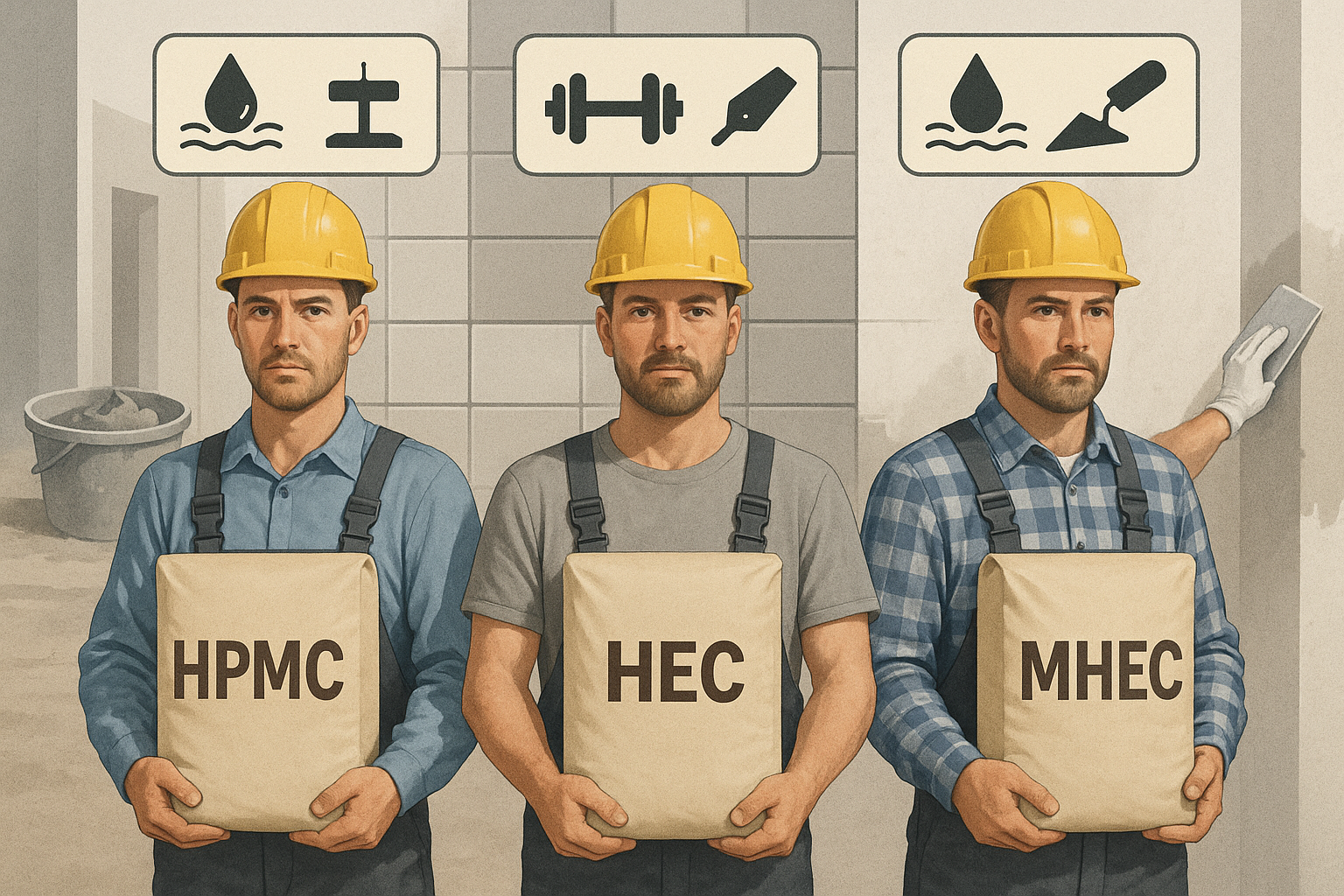

HPMC vs HEC vs MHEC

Many new buyers compare data sheets and still feel lost. I used to be the same when I first entered this industry. Today, I want to simplify this for you. I will explain how HPMC works, how it compares to MHEC and HEC, and how you can choose the right grade for your projects. Stay with me. After reading this, you will understand which one truly fits your mortar production.

What Is Hydroxypropyl Methyl Cellulose and How Does It Work in Mortars?

Many mortar failures come from weak water retention and poor consistency. If your formula cannot hold enough water, cement hydration breaks, tiles fall, and cracks appear. The right thickener prevents that and protects your brand.

Hydroxypropyl Methyl Cellulose improves mortar by holding water, increasing open time, preventing sagging, improving adhesion, and making mortar easier to apply. It makes mixes stable in different weather conditions and supports consistent strength development on-site.

HPMC in mortar

HPMC works inside cement systems like a performance booster. It holds water inside the mortar until cement reacts fully. This gives your workers more working time. It also helps the mix spread smoothly. In tile projects, HPMC stops tiles from sliding, so walls stay neat and safe. Below is a simple breakdown.

What HPMC Does in Mortars

- Keeps water inside the mix so cement cures fully

- Makes mortar smooth and easy to spread

- Improves adhesion between mortar and surface

- Stops tiles from sliding down

- Ensures better strength and durability

Key Benefits for Construction

| Performance | Result |

|---|---|

| Water retention | Strong bonding, fewer cracks |

| Thickening | Better workability |

| Open time extension | Longer time to adjust tiles |

| Anti-sag | Clean tile alignment |

| Temperature stability | Works in summer or winter |

For deeper understanding, you can also check technical notes from The American Concrete Institute and The European Federation for Construction Chemicals (EFCC) — both share good guidelines on water retention additives.

Key Differences Between Hydroxypropyl Methyl Cellulose, MHEC, and HEC

Many buyers think HPMC, MHEC, and HEC do the same job. That is not true. Each one has a different role. Choosing wrong means you spend more and still get complaints.

HPMC is best for cement-based and gypsum mortars. MHEC works well for plaster and tile adhesive. HEC is mainly for paints and coating systems due to its strong thickening effect and smooth brushing performance.

Manufacturers often test different grades before choosing. I help many buyers compare viscosity, gel strength, and water retention in our lab. I learned that the best choice depends on the application, weather, and binder system.

Main Differences

| Feature | HPMC | MHEC | HEC |

|---|---|---|---|

| Best application | Cement & gypsum mortars | Tile adhesive, plaster | Coatings & paints |

| Water retention | Excellent | Very good | Moderate |

| Workability | Very smooth | Smooth | Best for coating flow |

| Anti-sag | Strong | Good | Weak |

| Cost level | Medium | Lower | Medium |

| Temperature resistance | High | High | Moderate |

When to Use Each

- HPMC — Tile adhesive, wall putty, skim coat, self-leveling, gypsum plaster

- MHEC — Plastering, tile adhesive for cost-focused projects

- HEC — Interior & exterior paint, latex paint, thickening water-based systems

For technical reading, many engineers refer to Construction Chemicals Standards on ASTM International and EN building materials guidelines.

Which Cellulose Ether Should Construction Material Manufacturers Choose?

Many factories ask me: "If all three are good, which one should I buy?" I always answer: choose performance first, price second. Cheap raw materials do not save money when they create rework or customer complaints.

Construction mortar manufacturers should choose HPMC when stability and water retention matter the most. MHEC is a budget-friendly alternative for plaster and adhesive. HEC is the right choice for latex paint and coating systems. For cement mortars, HPMC remains the safest option.

I always suggest testing before buying bulk. Every market has different cement, sand, and weather. For example, clients in Southeast Asia often need higher water retention due to hot weather. Clients in Africa sometimes need higher viscosity for gypsum-rich formulas. Here is a guide that many of our partners follow.

Selection Guide Based on Product Type

| Application | Recommended Product | Reason |

|---|---|---|

| Tile adhesive | HPMC or MHEC | Strong bonding, anti-slip |

| Wall putty | HPMC | Smooth finish, long open time |

| Gypsum plaster | Modified HPMC | Controls setting and prevents cracking |

| EIFS / ETICS | HPMC | Stable bonding & flexibility |

| Latex paint | HEC | Best flow and leveling |

Tips for Purchasing

- Always test in your formula, not just rely on lab data

- Check viscosity stability in real weather

- Look for batch consistency

- Compare water retention under different temperatures

- Ask supplier for mortar field reports

If you want help choosing the right grade, you can email me or request free samples. I can also help test your formula and adjust viscosity and gel temperature.

Conclusion

HPMC gives the strongest performance for construction mortars. MHEC fits cost-focused plaster and adhesives. HEC belongs in coating systems. Choose based on application and real testing.

`