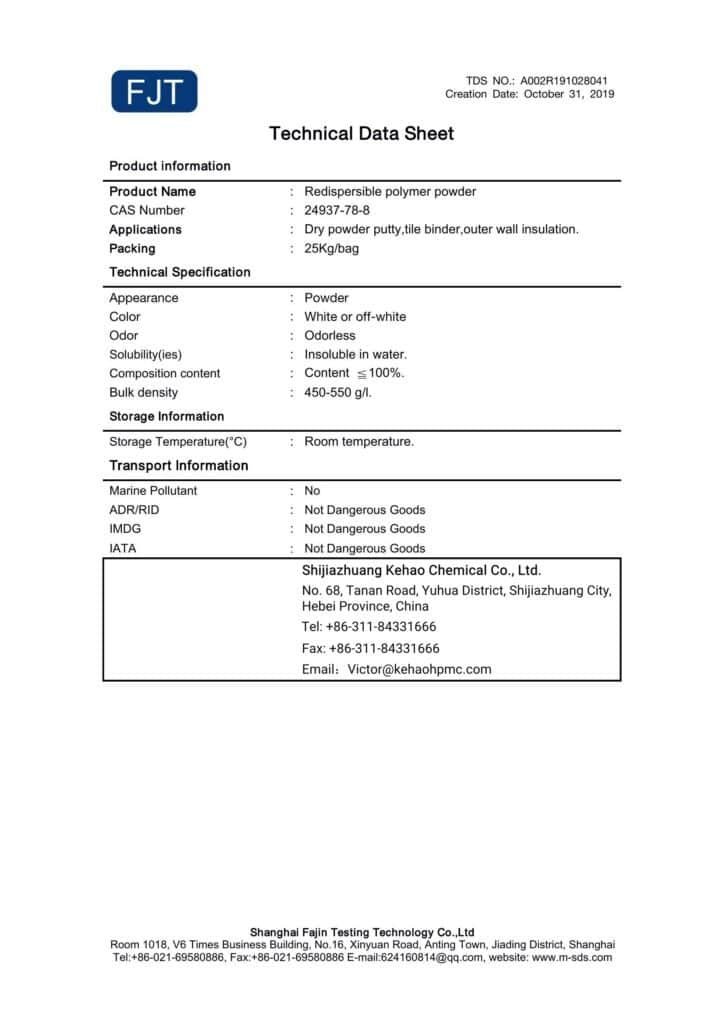

Kehao Redispersible Polymer Powder (RDP) is a white or off-whitewater-soluble liquid powder produced by spray-drying special water-basedemulsion.

Mostly based on vinyl acetate and ethylene. lt dissolves in water easilyand quickly forms emulsion .lt has high adhesion, water resistance, processabilityand heatinsulation.It is mainly used into the cement mortar as additive ofbuilding industrial.

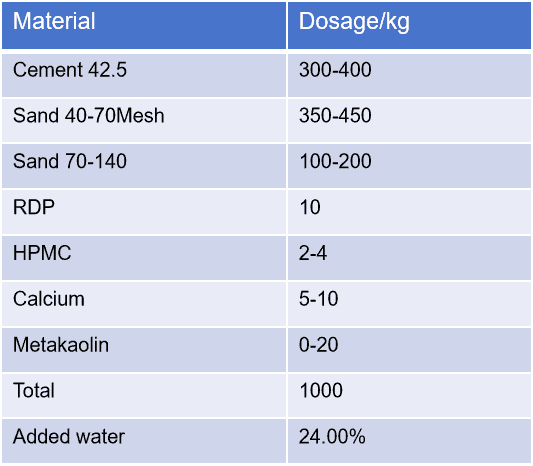

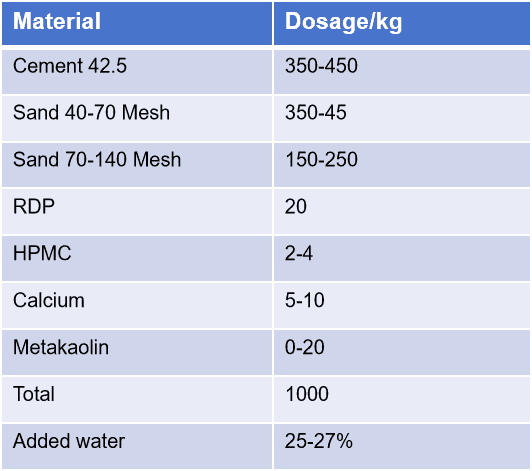

C1Tile adhesive Formulation

C2Tile adhesive Formulation

The main component of RDP powder is polymer resin, which has good bonding performance. By adding appropriate amount of RDP powder, the bonding between putty powder and substrate can be significantly improved, thus improving the adhesion of putty layer. This helps to ensure the durability and stability of the putty layer, effectively preventing the occurrence of phenomena such as cracking and peeling of the putty layer.

As RDP powder contains polymers, these polymers are able to form an elastic network structure in the putty layer, thus improving the putty powder’s crack resistance. This is especially important in exposed parts of the building, such as the exterior walls, to extend the service life of the building.

RDP powder has good water resistance, which can improve the water resistance of putty powder. In a humid environment, if the putty layer is not water-resistant, it is prone to mold, blistering, peeling and other phenomena. By adding RDP powder, the water resistance of putty layer can be improved, so that it can still maintain good adhesion in a humid environment.

RDP powder can also improve the construction performance of putty powder, such as easy to scrape, easy to sand and ductility, to ensure construction efficiency and construction quality. This helps to improve construction efficiency while reducing the occurrence of construction defects.

The polymer in the RDP powder forms a net-like structure in the mortar, which enhances the bonding force between the mortar and the substrate, enabling the mortar to be tightly bonded to a variety of substrates, effectively preventing cracking, peeling and other problems.

RDP powder, due to its excellent flexibility, can effectively absorb and release stress, preventing cracks in the mortar during the drying process. At the same time, RDP powder can also increase the toughness of the mortar, so that it can withstand greater deformation when subjected to external forces, effectively reducing the generation of cracks.

RDP powder has excellent durability and stability, which can effectively resist the erosion of UV rays and chemicals. It also improves the abrasion resistance and corrosion resistance of the mortar, thus extending the service life of the waterproof layer.

RDP powder has good thickening and stability, which helps to form a stable suspension system, so that the mortar is not easy to precipitate, delamination and other phenomena in the construction process. At the same time, it can also reduce the viscosity of the mortar and improve the construction efficiency.

RDP powder can form a dense film, effectively preventing the penetration of moisture and other harmful substances, which not only enhances the waterproof performance of the mortar, but also improves its resistance to chemical substances.

RDP powder is produced with environmentally friendly raw materials, non-toxic and harmless, friendly to the environment, in line with the requirements of green building.

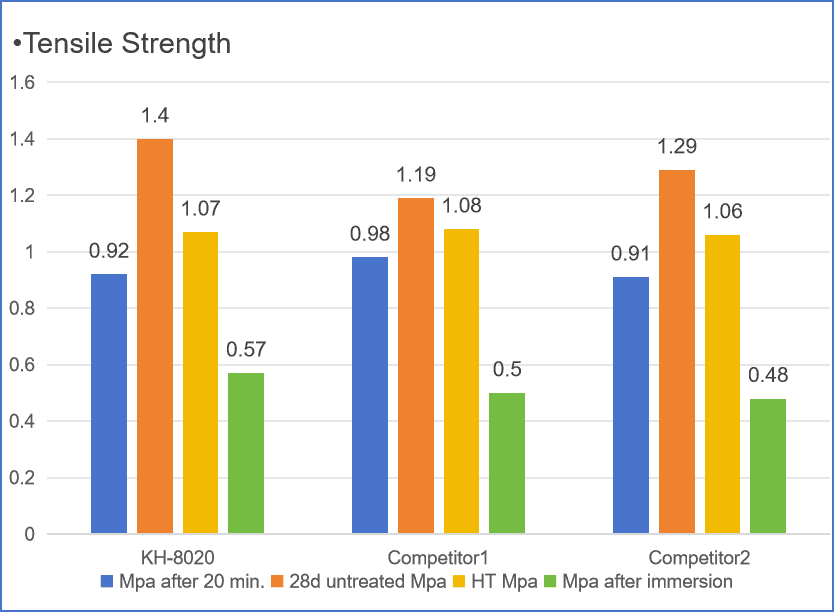

RDP has excellent bonding and adhesion, which can effectively improve the bonding between tiles and adhesives. Its molecular structure and tile surface has a strong affinity, can form a layer of elastic film, so that the tiles and adhesive to achieve self-locking interlocking, thus ensuring the firm adhesion of tiles.

RDP has good water retention, can effectively maintain moisture, avoid water evaporation too quickly, thus ensuring the construction effect of tile adhesive. At the same time, it also has good anti-cracking, can effectively prevent the tile adhesive cracks in the drying process, thus extending the service life of the tiles.

The construction performance of RDP is better, which can ensure the even coating and smooth construction of tile adhesive. It has better fluidity and wettability, which can make the tile adhesive better penetrate into the back of the tiles, thus improving the pasting effect. At the same time, it also has better anti-slip and anti-dangling properties, which can ensure the smooth construction of tile adhesive.

RDP has better water resistance and weather resistance, which can ensure good stability and durability of tile adhesive in the process of use. It can effectively resist the effects of moisture and climate change, thus ensuring the performance and service life of the tile adhesive.

RDP reacts chemically with inorganic fillers in gypsum mortar through its bonding properties and polar groups to form chemical bonding, thus significantly improving the bonding between gypsum mortar and various substrate surfaces and forming a strong bonding layer.

The addition of RDP can cross-link with gypsum molecules to increase the toughness of mortar. At the same time, the organic polymer material in the RDP can withstand greater deformation when the mortar is subjected to external forces, effectively reducing the generation of cracks.

RDP improves the durability of gypsum mortar by improving the compactness and waterproofing of the mortar, so that it can maintain stable performance under various environmental conditions.

RDP can improve the fluidity of mortar, reduce the phenomenon of delamination and segregation, make the mortar more uniform and consistent, and at the same time, reduce the shrinkage rate of mortar, reduce the phenomenon of cracking and deformation after construction.

KEHAO’s products meet the highest industry standards, ensuring quality and reliability. All our Redispersible Polymer Powder (RDP) have passed rigorous testing and are certified by national and international authorities. Trust in our commitment to excellence and compliance.

Tell us your application, we will provide customized solutions and technical guidance for you!

68 Tanan Road, Shijiazhuang, Hebei, China

Cellulose Ether Manufacturer

Typically replies within minutes

Any questions related to RDP/VAE?

Nancy

🟢 Online | Privacy policy

Chat for quality HPMC & factory prices!

Please tell us what you need and we will contact you as soon as we receive it!