Modern construction demands consistent quality. Many contractors struggle with mortar problems like cracking, sagging, and poor workability. When formulas fail, delays and cost overruns follow. Hydroxypropyl Methyl Cellulose (HPMC) solves these problems by improving mortar performance from mixing to curing.

Global contractors prefer Hydroxypropyl Methyl Cellulose because it improves water retention, workability, sag resistance, and strength development in dry-mix mortar formulations. Construction-grade HPMC ensures consistent mortar quality across different climates and job sites, making it essential in large-scale civil, commercial, and infrastructure projects.

Hydroxypropyl Methyl Cellulose for Mortar

Contractors need reliability. I have seen buyers lose projects because poor-quality dry-mix mortar caused sagging tiles and hollow plaster. Since then, I always tell clients: choose the right HPMC, and you protect your brand and schedule. Keep reading, because this decision affects real construction results.

How Hydroxypropyl Methyl Cellulose Enhances Dry-Mix Mortar Performance?

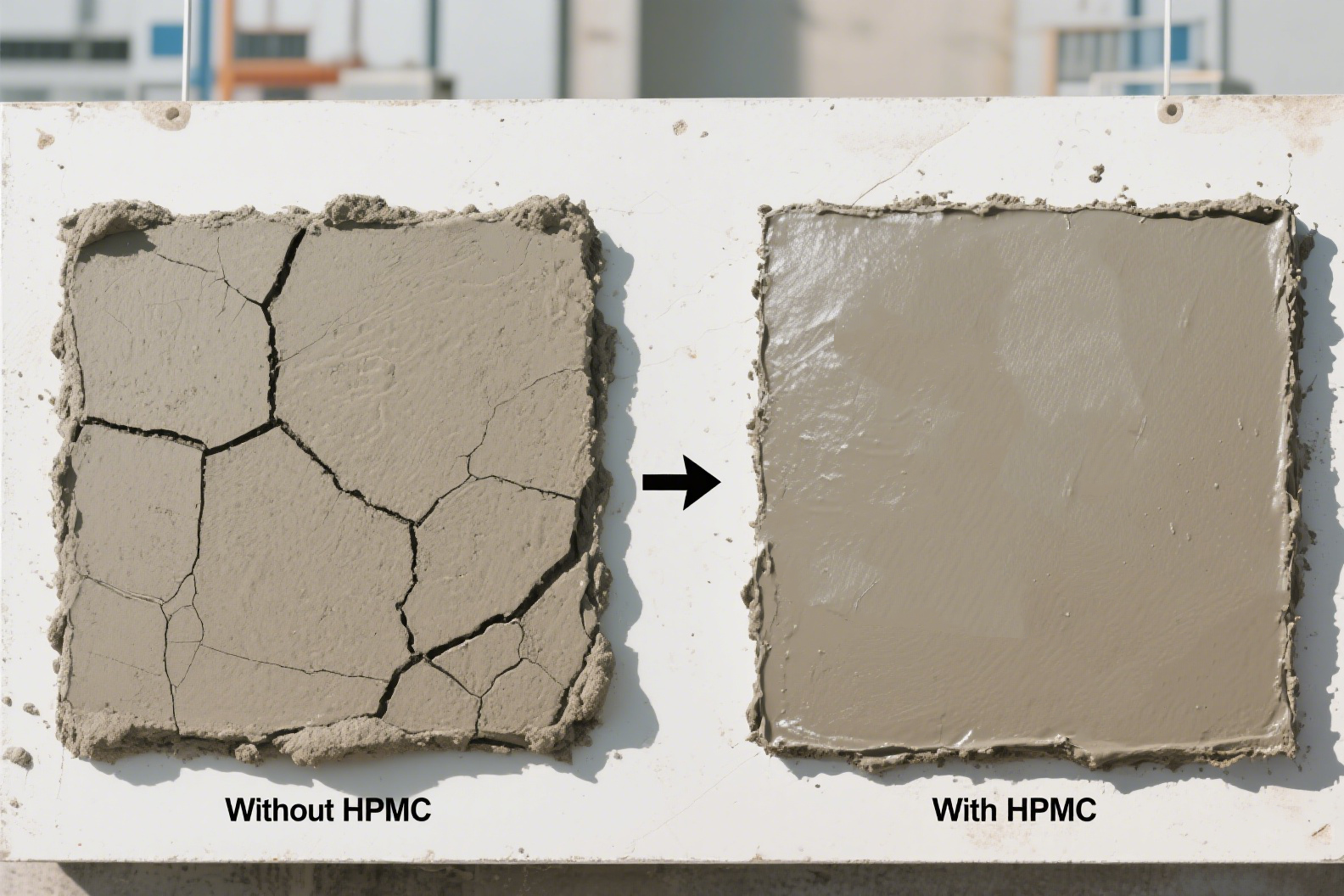

Many mortar failures come from poor water retention and weak adhesion. If the water evaporates too fast or the mix slips off the wall, the project suffers and workers waste material.

HPMC improves dry-mix mortar by increasing water retention, thickening, wetting ability, sag resistance, and adhesion strength. It keeps cement hydrated longer, ensures smooth spreading, avoids premature drying, and supports consistent strength development in tile adhesive, plaster, and skim coat.

How HPMC Improves Mortar Performance

I always explain HPMC performance to customers based on real jobsite feedback. The right grade avoids sagging tiles. The right viscosity gives smooth spreading. I have worked with clients who switched from low-cost cellulose ether and immediately saw fewer cracks and faster installation progress.

Key HPMC Performance Benefits

| Function | Practical Jobsite Result |

|---|---|

| Water retention | Prevents early drying and cracking |

| Thickening | Smooth, stable paste consistency |

| Workability | Easier spreading, less fatigue |

| Anti-sag | Tiles stay in place, even large tiles |

| Strength development | Strong, durable bonding |

How HPMC Works

Water Retention

HPMC holds water inside the mortar. Cement has time to hydrate fully. Workers get a longer open time. This prevents dry surfaces and hollow issues.

Thickening & Wetting

HPMC provides viscosity and helps wet the surface. The mortar spreads evenly. The worker uses less effort. The finish becomes smoother.

Sag Resistance & Stability

In tile adhesive, HPMC locks tiles in place. No sliding. Walls stay neat even with heavy tiles.

Strength & Durability

Good hydration means stronger bonding. Customers trust mortar that performs on every site.

Related standards:

- ASTM C1437 (flow of hydraulic cement mortar)

- EN 12004 tile adhesive performance requirements

(See: https://www.astm.org / https://standards.iteh.ai/catalog/standards/cen)

Why Contractors and Construction Companies Choose HPMC for Large-Scale Projects?

Large construction jobs need stable performance. When mortar behaves differently in different batches or climates, the whole supply chain suffers.

Contractors choose HPMC for large projects because it ensures consistency and efficiency. HPMC supports standard dry-mix systems, meets global construction requirements, and delivers predictable results for government projects, housing developments, and commercial buildings.

HPMC for Large Construction Projects

The first time I spoke with a government project procurement manager, he said one thing that stayed with me:

“We do not buy cheap materials. We buy stable success.”

He explained that rework costs millions. A good HPMC solves problems before they start.

What Large Projects Need

| Requirement | How HPMC Supports It |

|---|---|

| Quality consistency | Same mortar behavior from batch to batch |

| Labor efficiency | Faster installation and less rework |

| Climate adaptability | Works in hot, dry, or humid regions |

| Standardized formulas | Fits modern dry-mix design standards |

Global Trend Toward Dry-Mix Systems

Dry-mix mortar is growing fast worldwide. It saves labor time. It reduces waste. It supports green building goals.

Why Dry-Mix Systems Matter

- Better control of formula

- Less jobsite mixing errors

- Higher productivity

Global Adoption Drivers

- Government infrastructure plans

- Urban housing growth

- Environmental regulations

Reference:

Global dry-mix mortar market insights

(Search: “dry mix mortar global market report” by FMI, Fortune Business Insights)

Key Factors to Consider When Selecting Hydroxypropyl Methyl Cellulose for Mortar?

Not all HPMC is the same. Some dissolve poorly. Some fail in hot weather. Procurement teams must check the right technical indicators.

When selecting HPMC for mortar, consider viscosity, solubility, thermal gelation, water retention, consistency across batches, production capability, and testing data. Also review factory certifications and field trial reports before bulk purchase.

I always tell buyers: technical data + real jobsite tests = the only safe decision. One distributor in Southeast Asia upgraded to KEHAO HPMC and told me, “I finally sleep well. No more customer complaints.”

Key Selection Indicators

| Factor | What to Check |

|---|---|

| Viscosity | 40,000 – 200,000 cps depending on formula |

| Solubility | Fast dissolving, no lumps |

| Water retention | High rate for dry climates |

| Thermal stability | Works under high temperature |

| Factory capacity | Large-scale supply security |

| Certifications | ISO, test reports |

Supplier Due Diligence

Step 1: Check Lab Data

Ask for test sheets from accredited labs.

Step 2: Observe Quality Control

Stable batches matter. Visit or request production videos.

Step 3: Evaluate Real Site Performance

Test in mortar formula with real sand and cement sources.

Step 4: Check Export Record

Long-term shipping to your region means reliable grade consistency.

Related authority reference:

National Chemical Construction Materials Testing Center (China)

(You can search: 中国化建国家检测中心)

Conclusion

HPMC gives mortar stability, smooth workability, and strong bonding. Contractors choose it for reliable results at scale. The right HPMC supplier protects your projects and your brand.