How Does HPMC Impact the Workability of Dry Mix Mortars?

Are you tired of dry mix

Are you tired of dry mix

Tiles slipping off walls

Construction projects oft

Struggling to pick the pe

Problems with building ma

Cellulose Ether and Starch Ether are both derived from natural polymers, but they offer different properties and benefits. Cellulose Ether is more commonly used in construction and pharmaceuticals, while Starch Ether is often favored in food and industrial applications. Understanding their key differences will help you select the right material for your needs.

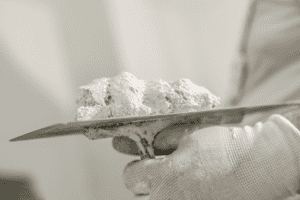

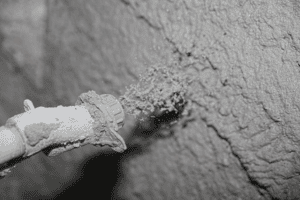

Cellulose ethers, including Hydroxypropyl Methylcellulose (HPMC), Methyl Hydroxyethyl Cellulose (MHEC), and Hydroxyethyl Cellulose (HEC), are water-soluble polymers that modify the rheological properties of construction materials. In putty powders, cellulose ethers provide critical functionality by improving consistency, adhesion, and ease of application. Each type of cellulose ether has specific properties that make it suitable for different applications.

HPMC is utilized in a wide range of industries, particularly in construction as a thickening agent and binder. It also enhances the performance of liquid detergents, personal care products, and various other applications due to its stabilizing and thickening properties.

When purchasing HPMC, focus on quality, certification, supplier reliability, and pricing. Look for consistent viscosity, water retention properties, and a supplier with robust logistics support and after-sales service.

HPMC (Hydroxypropyl Methylcellulose) enhances mortar by improving water retention, workability, and durability. It is a critical additive for creating high-performance building materials that meet diverse construction demands.

68 Tanan Road, Shijiazhuang, Hebei, China

Cellulose Ether Manufacturer

Typically replies within minutes

Any questions related to Cellulose Ether Manufacturer?

Nancy

🟢 Online | Privacy policy

Chat for quality HPMC & factory prices!

Please tell us what you need and we will contact you as soon as we receive it!